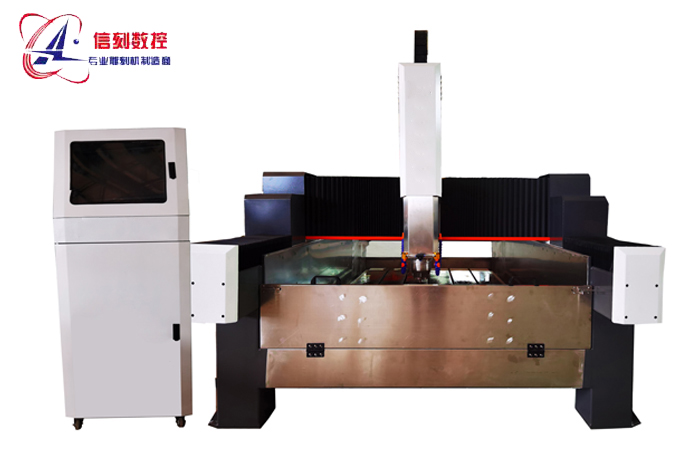

The Stone engraving machine is a mechanical equipment specially used for processing stone. It can control the tool through the CNC system to perform cutting, engraving, polishing and other processing techniques on the stone surface.

Make the stone produce various exquisite patterns and decorative effects.

In the fields of modern home decoration, garden landscape, public buildings and other fields, stone engraving machines are widely used to customize and process various stone products to meet the personalized needs of different customers.

To use a Stone engraving machine for customized processing, the designer first needs to produce corresponding design drawings according to the customer's needs.

Design drawings need to include detailed information such as the type, size, shape, pattern, etc. of the stone to be processed to ensure that the processing effect meets customer requirements.

Designers also need to determine the best processing plan and parameter settings based on the characteristics of the stone and the working principle of the Engraving machine.

Before actual processing, the design drawings need to be imported into the CNC system of the stone engraving machine and preprocessed and debugged.

By adjusting the tool's rotation speed, feed speed, cutting depth and other parameters, it is ensured that the engraving machine can accurately process the stone according to the design requirements.

In addition, you also need to pay attention to installing the cutting tools and ensuring that the working environment is clean and tidy to avoid affecting the normal operation and processing quality of the engraving machine.

Once the engraving machine is set up, machining operations can begin. During the processing process, operators need to monitor the operating status of the engraving machine at any time and adjust parameters and tool positions in a timely manner to ensure processing accuracy and efficiency. At the same time, pay attention to keeping the engraving machine and the surrounding environment clean, regularly cleaning chips and lubricating the lubrication system to extend the service life of the equipment.

After processing is completed, subsequent cleaning and finishing work is required. For cleaning, you can use vacuum cleaners, damp cloths and other tools to remove stone chips and dust and keep the stone surface smooth.

If necessary, the carved parts can also be ground and polished to further enhance the texture and beauty of the stone.

In general, using a stone engraving machine for customized processing is a complex and technical job that requires designers and operators to have extensive experience and expertise.

Only by fully understanding the characteristics of the stone and the working principle of the engraving machine can we ensure the quality and efficiency of processing. I hope the above content is helpful to you, thank you for reading.

Jibei Economic Development Zone, Jinan City, Shandong Province, China

Tel:+86-138-6266-6677

Email:yang@xkcnc.com

Copyright © 2022 Jinan Xinke CNC Machinery Co., Ltd.

Comment

(0)